Operation

Information on the CLPS-LIMS information

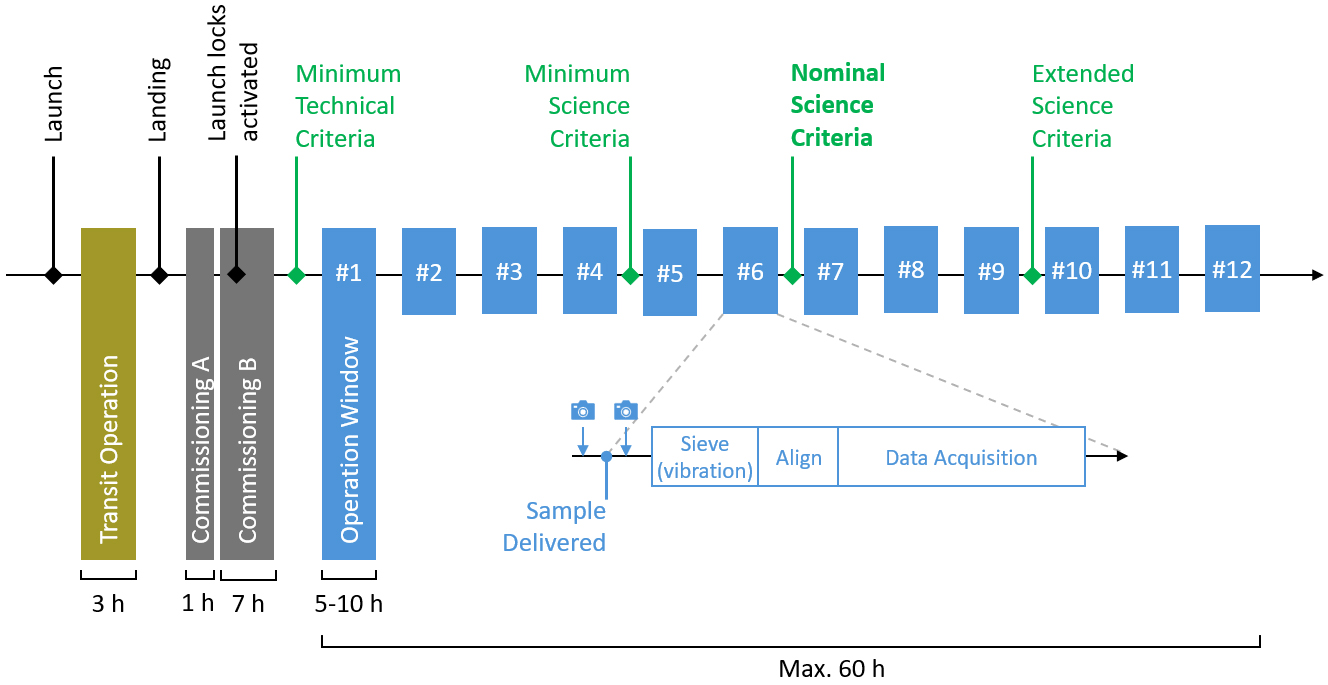

Following the launch of the mission, the CLPS-LIMS operators at the University of Bern will operate the CLPS-LIMS system for the first time during transit to the Moon (Transit Operation). This will enable them to check the system’s top-level functionalities and health status before it arrives on the lunar surface. Once the system arrived safely on the lunar surface, the CLPS-LIMS operators will start the commissioning phase. During this phase the various sub-systems will be tested, heated up to their nominal temperatures, and first measurements will be conducted on the two reference samples (stainless steel and basalt samples) integrated on the carousel. These measurements demonstrate that the minimum technical criteria have been, showcasing the first in-situ operation of the LIMS technology on a body in our solar system.

Following the commissioning phase, CLPS-LIMS can request up to 12 samples from the lunar surface to be delivered by the sample delivery system of the spacecraft, with a total measurement time not exceeding 60 hours. The sampling location will be imaged for each sample delivery, followed by imaging of the funnel once the sample is delivered. Sieving through vibration is initiated, and once the sample material on the carousel is in front of the mass analyzer aperture, the chemical composition analysis can start.

The CLPS-LIMS mission timeline is displayed in the following.

The spacecraft provides lunar regolith in a single delivery of 50 – 100 cm3 with grain sizes no larger than 5 mm for the funnel system of the CLPS-LIMS SHSM. The funnel system comprises two sieves and a vibration motor, which sieves the regolith material down to a maximum grain size of Ø 1 mm and guides the material towards the carousel system of the CLPS-LIMS system. Once the material arrives at the carousel, three shaping brushes and a skimmer guide and prepare the lunar regolith to the sample cavity of the carousel. After the brush and skimmer system a surface roughness of nominal +/- 200 µm is realised, which is required for accurate material ablation and ionisation. The carousel moves the material in front of the mass analyzer, where material ablation and ionization are initiated. A cleaning brush then removes the material from the cavity, allowing the carousel cavity to be refilled by requesting the next sample delivery from the spacecraft.